The WorkSafe website will be unavailable on Tuesday 16 September from 12pm–5pm due to planned maintenance.

Our other online services, including the online services portal(external link) and Energy Safety portal(external link), will remain available.

To notify us of an injury, illness or incident at work, visit our online services portal(external link). For urgent notifications, please call us on 0800 030 040. For general or non-urgent enquiries, email us at info@worksafe.govt.nz.

Paper cutting guillotines are used to cut stacks of paper or cardboard.

While this guidance has not been updated to reflect current work health and safety legislation (the Health and Safety at Work Act 2015 and regulations), it may still contain relevant information and practices to keep workers and others healthy and safe.

Please read this guidance in conjunction with all relevant industry standards that apply to you as a PCBU. This guidance will be progressively reviewed and either updated, replaced with other guidance, or revoked.

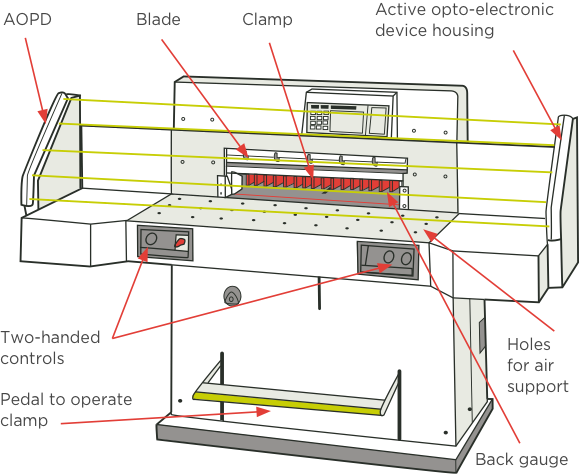

Guillotines have a clamp that secures the paper in a stack, and a back gauge to control the position of the cut by positioning the stack. Similar to the action of scissors, the blade shears the paper, starting at one side of the stack.

Because the stack of paper is usually a few centimetres high, safety systems on the operator’s side of the guillotine will not necessarily isolate the clamp and blade hazards. However, other safety precautions can be put in place.

Figure 1: Paper cutting guillotine

Hazards

- Lifting and turning

- Repetitive movements

- Entrapment with clamp and blade

- Contact, impact or entanglement from moving parts

- Noise

- Slips, trips and falls

- Impact or entanglement from unexpected movement (during maintenance, cleaning & repairs)

Personal Protective Equipment (PPE)

- Ear protection

- Eye protection

- Foot protection

Tasks

Lifting and turning

Repetitive movements

Harm

- Strain injury

- Cuts

Controls

- USE tables equal in height to the guillotine table.

- POSITION guillotines AWAY from busy walkways to limit interference.

- Blades SHOULD have handling gear, for safe lifting and moving.

Stacks of paper may be heavy and awkward to lift. Tables SHOULD adjust upward as the paper stack goes down. They SHOULD have air support to minimise friction between table and paper, reducing the required effort.

Task – Make the cut

Hazard

Harm

- Crush injuries

- Cuts

Controls

- USE fixed or interlocked guards, or presence sensing devices, to prevent access to clamp and blade.

- USE a push stick to clear items.

- ENSURE adequate lighting.

- PROVIDE support for any parts that may fall and cause injury.

- During the cut, keep both hands:

- on two-handed controls to prevent one control being held down

- ready at the start buttons – starting the cut with a pedal is unsafe.

- MAXIMISE clamp pressure at 500 Newtons (roughly 50 kg) before stroking begins.

Small items require close reach to clamp and blade, sometimes under the clamp and blade. A knife edge on a heavy piece of steel can be hazardous if control circuits fail, and the clamp and blade descends.

Hazard

Harm

- Potential crush injuries

- Bruising

- Fractures

Controls

- USE fixed or interlocked guards, or presence sensing devices, to prevent access to clamp and blade.

- USE a push stick to clear items.

- ENSURE adequate lighting.

- PROVIDE support for any parts that may fall and cause injury.

- During the cut, keep both hands:

- on two-handed controls to prevent one control being held down

- ready at the start buttons – starting the cut with a pedal is unsafe.

- MAXIMISE clamp pressure at 500 Newtons (roughly 50 kg) before stroking begins.

Moving parts can entangle anyone reaching into the back. Parts may fall when cuts are measured from behind the blade but controlled from the front. Full pressure MUST NOT occur until the cutting stroke begins, and when the paper is clamped securely at full pressure.

Guards

Interlocked guards

MUST prevent the start of a cut until they are closed.

If they are opened during a cut they MUST stop movement of the clamp, blade, or gauge before reach to a hazard can occur.

If they can’t stop movement, the guards MUST be secured closed until movement stops.

Sweep away guards

A modern guillotine may have:

- an active optoelectronic protective device (AOPD) fitted, or

- light curtain with control system, which MUST ensure that the light curtain stops movement of the guillotine before a hazard can be reached.

If the guillotine is a full revolution type, powered by a flywheel, the clamp and blade must be interlocked against faults allowing unexpected movement between intentional powered strokes.

Other (non-mechanical) hazards

Hazard

Noise

Harm

- Hearing loss or damage

Controls

- REDUCE noise levels by isolating machines or enclosing within noise barriers.

- ASSESS noise levels.

- ARRANGE hearing screenings.

- ALWAYS WEAR hearing protection.

Hazard

Harm

- Contact or impact injuries

- Crush injuries

- Cuts

- Bruising

- Fractures

Controls

- ENSURE housekeeping procedures are in place.

- WEAR suitable footwear.

- Keep walkways clear of tools, materials, and electrical leads.

- Provide:

- storage for materials

- adequate lighting

- anti-slip surfaces

- rails where needed

- Secure any ladders.

- KEEP equipment safely maintained.

Task – Maintenance, cleaning & repairs

Hazard

Harm

- Cuts

- Bruising

- Fractures

Controls

- LOCK-OUT all power supplies before maintenance, cleaning and repairs.

- USE a transparent guard if power is needed.

- PROVIDE adequate support for parts that may fall and cause injury.

- KEEP up-to-date safety procedures, and ARRANGE regular inspections by a competent person.

- REMOVE guillotines that fail inspection, and DO NOT USE until repaired or replaced.

- CARRY OUT a new hazard assessment when a guillotine is altered, and make necessary safety improvements.

- APPLY any manufacturer modifications to the original control circuits.

- A blade SHOULD have its own handling gear, to allow safe lifting and moving.

Instructions MUST be in a language understood by operators.

Download fact sheet

Last updated