The WorkSafe website will be unavailable on Tuesday 16 September from 12pm–5pm due to planned maintenance.

Our other online services, including the online services portal(external link) and Energy Safety portal(external link), will remain available.

To notify us of an injury, illness or incident at work, visit our online services portal(external link). For urgent notifications, please call us on 0800 030 040. For general or non-urgent enquiries, email us at info@worksafe.govt.nz.

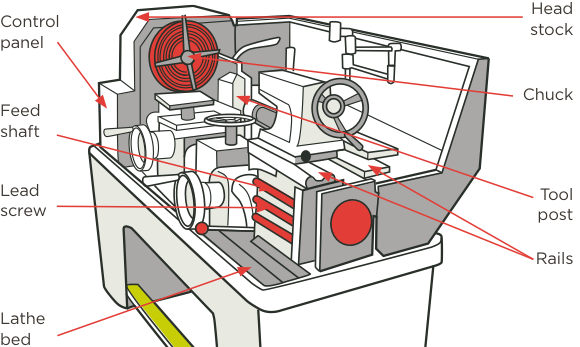

Metal turning lathes, particularly centre or engine lathes, are commonly used for machining metal parts.

A workpiece secured in a chuck is turned against a tool which cuts metal from the workpiece. Parts are created by turning the workpiece in one or both ends of the lathe, and changing its shape using tools with specific cutting edges.

Figure 1: Metal turning lathe

Hazards

- Heavy lifting

- Contact, impact or entanglement from moving parts/ loose objects

- Contact with metal chips or swarf

- Contact with liquid coolant

- Leaking hydraulic hoses

- Inappropriate tooling and polishing techniques

- Noise

- Slips, trips & falls

- Contact, impact or entanglement from unexpected movement (during maintenance, cleaning & repairs)

Personal protective equipment (PPE)

- Ear protection

- Eye protection

Tasks

Heavy lifting

Harm

- Strain injury

Controls

- USE a mechanical lifting aid when necessary.

- DO NOT operate the lathe during loading and unloading.

Task – Secure the workpiece & make the cut

Hazard

Harm

- Deep cuts or amputation

- Bruising

- Fractures

Controls

- ENCLOSE parts (eg. Chuck keys, tools or swarf) in interlocked guards to avoid being hit.

- USE the appropriate chuck for the workpiece.

- KEEP the headstock free of loose items.

- AVOID wearing loose clothing, jewellery or gloves - they increase the risk of entanglement.

- PLACE lathe controls to AVOID reaching through the work zone.

- Workpieces SHOULD NOT extend beyond the headstock of the lathe. If they do, adequate support MUST be provided.

Moving parts can include:

- drive gears

- chucks/chuck keys

- lead and feed screws

- tools or swarf

- oversized or inadequately secured workpieces.

Chuck keys can be spring loaded to eject when the operator’s hand is removed. The interlocked guard over the chuck cannot close until the key is removed.

Hazard

Harm

- Burns or skin damage

Controls

- KEEP chips of metal contained.

Other (non-mechanical) hazards

Hazard

Harm

- Breathing difficulties and skin damage

Controls

- ENSURE that cooling fluids and lubricants are:

- CONTAINED to prevent harm

- TREATED or REPLACED in accordance with manufacturer’s instructions.

Hazard

Leaking hydraulic hoses

Harm

- Leakages may penetrate skin

- Hand pain

- Tissue and muscle damage

- Puncture wounds

Controls

- Leaking oil, or bulging or abraded hose walls, MUST have faulty parts replaced.

- DO NOT use hands or fingers to detect hydraulic oil leaks.

- If oil seeps onto anyone’s skin, or someone working near hydraulic oil under pressure thinks they were bitten by an insect, they MUST be TAKEN to hospital, with full information presented to medical staff.

- APPLY a programme preventive maintenance (hydraulic hoses and hydraulic hose couplings).

Hazard

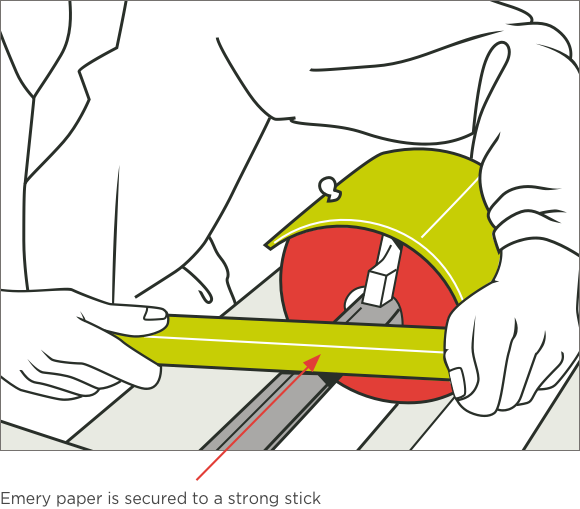

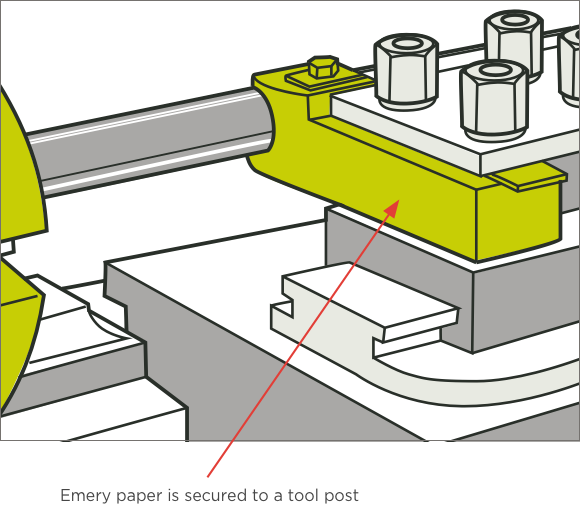

Entanglement from inappropriate tooling and polishing techniques with emery paper

Harm

- Cuts

- Crushing injuries

Controls

- AVOID wearing loose clothing, jewellery or gloves – they increase the risk of entanglement.

- Emery paper MUST be securely held by the ends – DO NOT wrap around hands or all the way around the workpiece.

Tools MUST be buffed and polished. If they have scratches or gashes in them, the metal is more likely to catch and tear as it is spinning.

Figure 2: Emery paper is secured to a strong stick

Figure 3: Emery paper is secured to the tool post

Figure 4: Emery paper is secured in a “nutcracker”

![[Image] Worker securing emery paper in a "nutcracker"](/assets/Topic/Machinery/Metal-turning/manufacturing-metal-turning-lathes-figure-4.png)

Hazard

Noise

Harm

- Hearing damage or loss

Controls

- REDUCE noise levels by isolating machines or enclosing within noise barriers.

- ASSESS noise levels.

- ARRANGE hearing screenings.

- ALWAYS WEAR hearing protection.

A safe noise level over an eight hour day is 85dB(A). A metal turning lathe may exceed this noise intensity. Hydraulic pumps can also be noisy.

Hazard

Slips trips and falls

Harm

- Trapping

- Cuts

- Bruising

- Contact with liquids

Controls

- KEEP up-to-date housekeeping procedures.

- KEEP the area around lathes clear of slip and trip hazards.

Task – Maintenance, cleaning & repairs

Hazard

Harm

- Cuts

- Bruising

- Fractures

Controls

- LOCK-OUT all power supplies before maintenance, cleaning and repairs.

- DO NOT clean the lathe while it is operating.

- KEEP written safety procedures, and arrange regular inspections by a competent person.

- REMOVE or LOCK-OUT lathes that fail inspection, and DO NOT USE until repaired or replaced.

Download fact sheet

Last updated