The WorkSafe website will be unavailable on Tuesday 16 September from 12pm–5pm due to planned maintenance.

Our other online services, including the online services portal(external link) and Energy Safety portal(external link), will remain available.

To notify us of an injury, illness or incident at work, visit our online services portal(external link). For urgent notifications, please call us on 0800 030 040. For general or non-urgent enquiries, email us at info@worksafe.govt.nz.

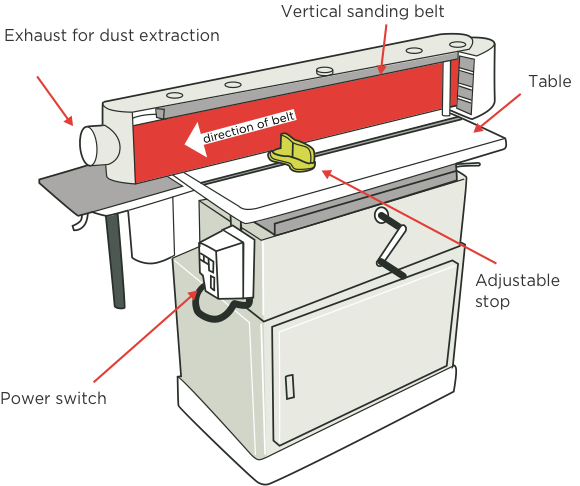

A linisher turns a belt or disc of abrasive material to smooth a workpiece, creating a level, even surface. It can also be used to polish materials. Materials are usually wood or metal but, can be plastic also.

While this guidance has not been updated to reflect current work health and safety legislation (the Health and Safety at Work Act 2015 and regulations), it may still contain relevant information and practices to keep workers and others healthy and safe.

Please read this guidance in conjunction with all relevant industry standards that apply to you as a PCBU. This guidance will be progressively reviewed and either updated, replaced with other guidance, or revoked.

The belt of a linisher belt is continuous and runs over rollers. One of the rollers is driven by an electric motor.

Discs and belts are made of abrasive material bonded to a backing of paper and cloth.

Figure 1: Linisher

![[Image] Linisher with labels and red arrows pointing to key components and direction that belt moves in](/assets/Topic/Machinery/Linishers/manufacturing-linishers-figure-1.png)

Figure 2: Linisher used for smoothing wood

PPE:

There will be linisher operations where a dust mask alone is adequate protection.

Figure 3: Linisher with sanding disc and sanding belt, both driven by the same motor

![[Image] Linisher with sanding disc and sanding belt, showing labels and red arrows pointing to key components and direction that belt moves in](/assets/Topic/Machinery/Linishers/manufacturing-linishers-figure-3.png)

Hazards

- Nips trapping hands or fingers

- Contact or impact from thrown workpieces

- Entanglement with turning wheel or disc

- Contact or impact from abrasive discs or belts

- Sparks and hot metal

- Dust

- Noise

- Contact, impact or entanglement from unexpected movement (during maintenance, cleaning & repairs)

Personal protective equipment (PPE)

- Eye protection

- Foot protection

- Dust protection

Tasks

Harm

- Deep cuts

- Crush injuries

- Fractures

Controls

- HOLD workpieces firmly on the table.

- DO NOT approach the nips.

Hazard

Nips between disc and table, or between abrasive belt and stop, trapping hands or fingers

Harm

- Deep cuts

- Crush injuries

- Fractures

Controls

- ADJUST table or stop within 2 mm of the abrasive disc or belt.

Hazard

Harm

- Bruises

- Fractures

Controls

- HOLD workpieces firmly against the abrasive belt or stop, using tools or jigs.

Loosely held workpieces are thrown by the abrasive belt.

Hazard

Harm

- Scalping if hair is caught

- Crushed body parts

Controls

- TIE back long hair or beards.

- WEAR tight fitting clothes, especially sleeves, without long ties.

- DO NOT wear jewellery.

Loose clothing, long hair, and jewellery can wrap around spinning wheels.

Hazard

Harm

- Deep cuts

- Bruising

- Fractures

Controls

- ENSURE POWER CONTROLS are within easy reach to enable rapid shut down when damaged discs or belts are detected.

- INSPECT belts before use.

- LISTEN for noise as the belt starts to break and stop the linisher or stand aside.

- AVOID damage to belts.

- Use belts within a SHORT TIME of purchase.

- DISCARD damaged belts and discs.

Damaged belts will worsen during use, and may become a projectile, hitting the operator or other people close by.

Task – Other (non-mechanical) hazards

Hazard

Sparks and hot metal

Harm

- Burns to skin

- Eye injuries

- Property damage

Controls

- CLEAN UP flammable dust from grinding flammable material, before grinding iron or steel which may produce hot sparks.

- REPLACE worn belts or discs before heat builds up excessive.

Flammable material may ignite.

Hazard

Dust

Harm

- Breathing problems

- Lung damage

- Eye irritation or damage

- Worsening of existing health problems

- Potential fire or explosion

Controls

- USE ventilation to extract dust as much as possible.

- CLEAN up surface dust as quickly as possible.

- Vacuum cleaners MUST be designed for cleaning dust. Blowing flammable dust with compressed air will only place it elsewhere.

- USE dust extraction equipment to minimise dust getting in the operator’s breathing zone.

- ALWAYS USE respiratory protection.

- ALWAYS WEAR eye protection.

Dust from metals, woods and fibre boards, causes respiratory harm.

Finely divided metal, wood, or plastics dust that is not contained and controlled may fuel a fire or explosion.

Hazard

Noise

Harm

- Hearing damage or loss

Controls

- REDUCE noise levels by isolating machines or enclosing within noise barriers.

- ASSESS noise levels.

- ARRANGE hearing screenings.

- WEAR hearing protection.

Task – Maintenance, cleaning & repairs

Hazard

Contact, impact or entanglement from unexpected movement

Harm

- Bruising

- Fractures

- Deeps cuts

Controls

- LOCK-OUT all power supplies before maintenance, cleaning and repairs.

- LEAVE the machine in a safe, clean, tidy state.

- TEST machines regularly to ensure they are operating safety.

- ARRANGE regular inspections by a competent person. Inspect for damage or wear.

- REMOVE linishers that fail safety tests and inspections, and DO NOT USE until repaired or replaced.

A safe noise level over an eight hour day is 85dB(A). A linisher may exceed this noise intensity. Instructions MUST be available in a language understood by employees. Inspections MUST be in accordance with the manufacturer’s instructions.

Download fact sheet

Last updated