This technical bulletin is for owners and users of mobile stock loading ramps.

Background

Mobile stock ramps are a common piece of farm equipment, used during the loading and unloading of stock. Poorly designed or maintained ramps, and poor practice using them, pose a real danger to those who use them. Workers like stock truck drivers and farm workers need to be aware of the risks associated with these ramps.

Risks associated with stock loading ramps can include:

- the ramp falling on workers under it

- persons being crushed between the ramp and truck when lining them up

- stock crushing persons on the ramp

- workers’ hands being caught when engaging or disengaging the lever lowering the ramp

- slips, trips, or falls.

Design-related failures

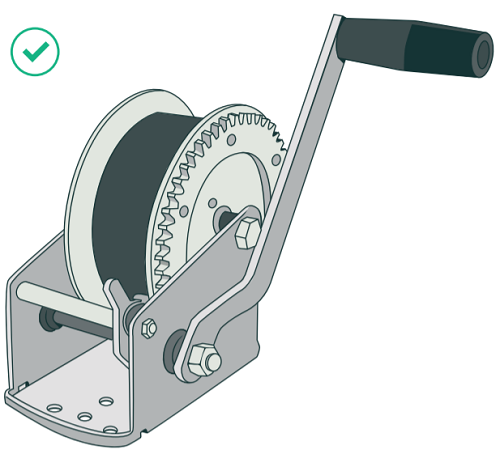

There’s a risk to workers when a ramp has no braking system, for example, a cog and pawl style winch that only locks while going up and does not lock when going down. This means the ramp is able to lower without control. All loading ramp winches should have a self-activating, automatic brake ratchet system to prevent unwinding hazards.

Maintenance-related failures

Like any other piece of machinery, stock loading ramps should be checked and maintained regularly. Wear and tear can compromise braking mechanisms and other safety critical components.

Good practice

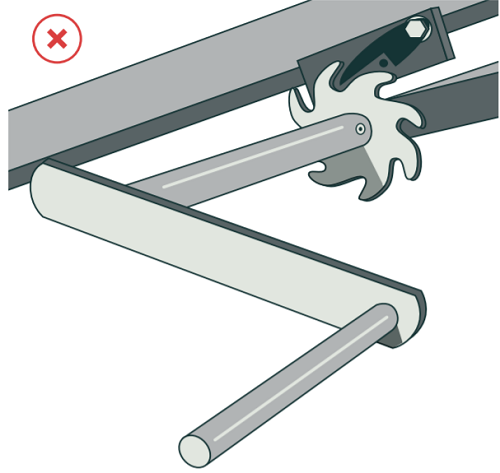

No person should go under loading ramps. Workers should never work under any suspended load, whether it’s to take shortcuts or to align the ramp with gates or trucks. If the ramp lowers without warning, a worker beneath it can be seriously injured.

Controls

Owners and operators of loading ramps should:

- only use ramps fitted with an automatic brake winch system, and be within the winch’s rated capacity

- put a maintenance schedule in place to regularly and effectively clean, inspect, and service the ramp and brakes. This also includes making sure the operating mechanism is adjusted correctly, with any play in the winch handle addressed before further use.

- inform all workers on the risk of working under a suspended load

- make sure no workers position themselves under a suspended load

- keep all persons out of the path of the ramp and vehicles when aligning for stock loading.

If work needs to be done under the ramp, put controls in place like chocks so the ramp cannot move, and use locking pins, props, or similar so it cannot lower any further.

Related information

Last updated